Dynamic Modulus Test

Overview

The dynamic modulus test is a cyclic test used to determine the properties of Hot Mix Asphalt. This test is used to determine both the dynamic complex modulus (also known as the elastic modulus) and the phase angle, which are both important parameters for pavement design.

The dynamic modulus results are used to evaluate the response of the asphalt pavement to dynamic loading conditions. This means that the dynamic modulus test can be used to determine asphalt’s resistance to rutting over the course of time, as both the recoverable and permanent deformations are measured during the test. The phase angle of the asphalt can also be determined from the dynamic modulus test, which is a measure of the lag between the maximum stress and the maximum strain on the asphalt and is a function of the elasticity of the asphalt. For a perfectly elastic material, the phase angle is equal to zero degrees and for a perfectly viscous material, the phase angle is equal to 90 degrees.

The dynamic modulus is determined by applying a sinusoidal load to a cylindrical asphalt specimen under varying frequencies and temperatures while measuring the deformation of the specimen. From this data, the dynamic modulus can be found for various temperatures, which can be directly translated to how the asphalt tested will behave in the environment under the tested loading conditions.

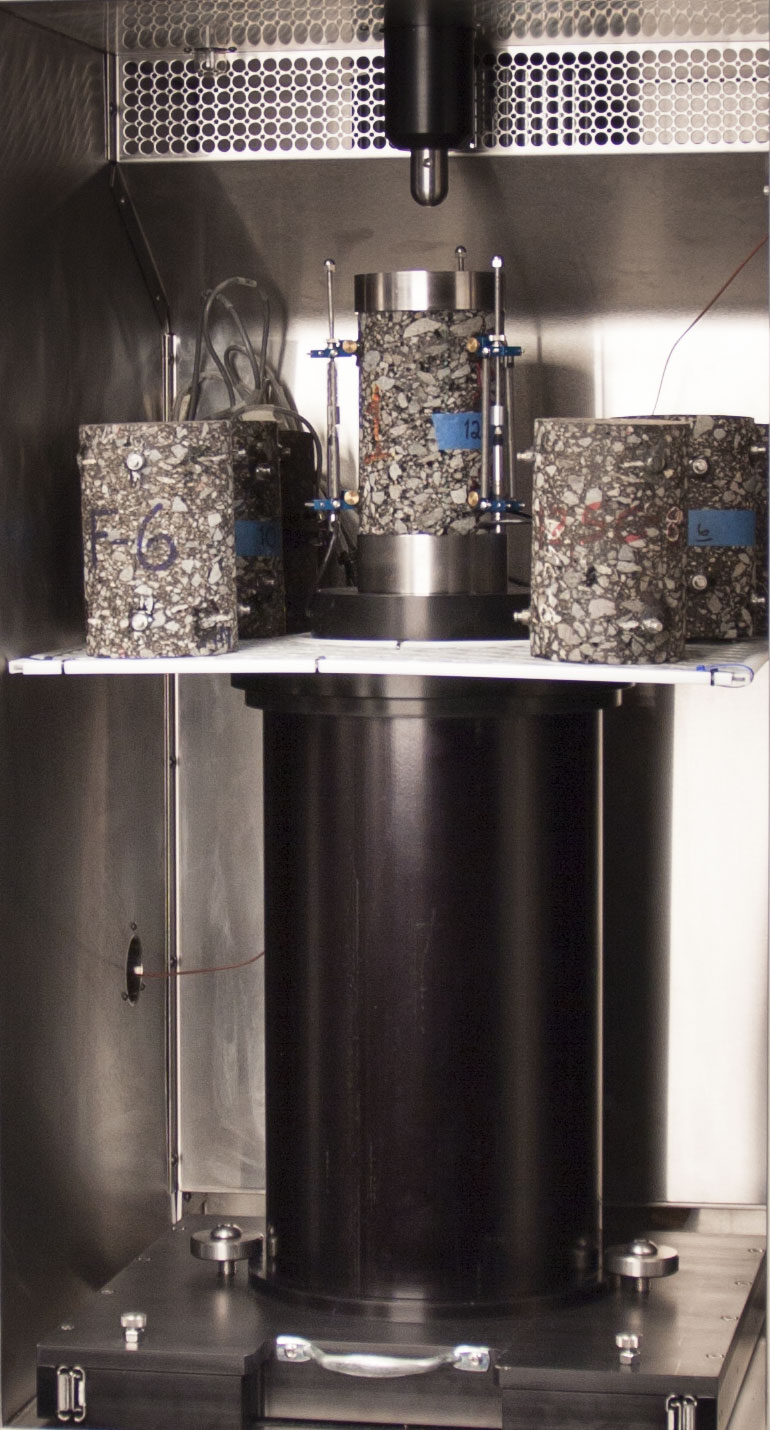

Dynamic Modulus Testing Equipment (Courtesy of GCTS)

How is a Dynamic Modulus Test Performed?

The dynamic modulus test is performed by placing a cylindrical asphalt specimen in a testing chamber and applying an axial load at varying frequencies. The stress applied to the specimen is generally determined based on the temperature at which the specimen is tested. The table below shows the stress ranges that should be used when testing specimen of various temperatures.

After determining the stress that the specimen will be tested at, the stress is applied sinusoidally at 25 Hz for 200 cycles to condition the specimen. Then the stress is applied at 25 Hz for 200 cycles, 10 Hz for 200 cycles, 5 Hz for 100 cycles, 1 Hz for 20 cycles, 0.5 Hz for 15 cycles, and 0.1 Hz for 15 cycles. After all of the cycles at a certain frequency have been performed, the specimen should be allowed to rest

for two minutes before beginning the text at the next frequency.

After performing all the loading cycles at one frequency, the specimen is tested at a different ambient temperature, following the temperatures listed in the table above. The lowest temperature should be tested first and moved incrementally to the highest temperature. Generally, once the temperature has been increased in the testing chamber, the operator must wait up to 6 hours before performing the next test to allow the chamber and the specimens to equilibriate at the new temeprature. Multiple specimens should be tested at each temperature to get average values for a sample of asphalt.

For each test, the stress, recoverable strain, and permanent strain should be recorded by use of a load cell and three LVDTs attached directly to the specimen. From these values, the dynamic modulus and phase angle of the asphalt can be determined.

What does a Dynamic Modulus Test Specimen Look Like?

A typical asphalt specimen is approximately 100 mm (4 in.) in diameter and 150 mm (6 in.) in height. These specimens are typically prepared by using a Superpave Gyratory Compactor to create and compact the specimen and a grinder and saw to cut the specimen to size and ensure the edges are flat, smooth, and parallel. Specimens can be created with different particle sizes, void ratios, binder types, and other differing parameters to see how each affects the dynamic modulus of the asphalt.

How are Dynamic Modulus Specimen Characteristics Determined?

The average dynamic modulus should be calculated for each tested frequency. This can be done using the following equation.

In this equation,

εo=Peak (Maximum) Strain

εo=Peak (Maximum) Strain

Φ=Phase Angle (in Degrees)

Φ=Phase Angle (in Degrees)

ω=Angular Velocity

ω=Angular Velocity

t=Time (in Seconds)

t=Time (in Seconds)

The phase angle can be directly calculated as the shift between the stress and strain curves during measurement, so this value is used to calculate the dynamic modulus for each frequency. A graph can be created at each temperature with the testing frequency on the x axis and the dynamic modulus on the y axis. A sample graph is shown below.

As shown, the data should be plotted with a log scale on both axes. After creating these seperate curves, a master curve must be created. This curve combines all the five previous curves into one curve, designed to predict the dynamic modulus at many frequencies. This curve is constructed for a reference temperature, usually about 21°C. The curves at other temperatures are shifted to this reference temperature. Therefore, the low temperature tests best represent the dynamic modulus at high frequencies while the high temperature tests best represent the dynamic modulus at low frequencies. This is first done by calculating the time of loading at the reference temperature, tf, which is equal to the time of loading during the test (1/frequency) divided by a time shift factor, which is a function of the testing temperature. Each value of the dynamic modulus of the five curves is shifted according to their testing temperature, and a final master curve is created from data. A sample master curve is shown below.

This curve should fit the following equation

In this equation,

δ=Minimum Value of Log (E*)

δ=Minimum Value of Log (E*)

δ+α=Maximum Value of Log(E*)

δ+α=Maximum Value of Log(E*)

tr=Time of Loading at Reference Temperature

tr=Time of Loading at Reference Temperature

β, γ=Parameters Describing the Shape of the Function

β, γ=Parameters Describing the Shape of the Function

This final master curve equation can then be used to predict the dynamic modulus of the sample at any frequency, which is important when designing roads to withstand cars, trucks, earthquakes, and other unforseen events.

Keywords: Dynamic Modulus — Elastic Modulus (E*) — Dynamic Modulus Test — Dynamic Modulus Tester — Dynamic Modulus Testing System — Dynamic Modulus Testing Machine — Dynamic Modulus Testing Equipment — Dynamic Modulus Testing Apparatus — Phase Angle — Stress — Strain

© 2016 Geotechnical Consulting and Testing Systems, LLC. All Rights Reserved.